Product Liability is the legal responsibility of a manufacturer, distributor, or retailer to guarantee that the products they make and sell are safe for the intended use. When a product has an inherent defect in its design, components or manufacturing process, and leads to injury or loss due to failure to perform its purpose safely, then it could fall under strict liability for product defects as per tort law.

In such cases both direct devices (the ones who manufactured, sold and/or distributed the devices) as well fundamental manufacturers can become liable for damages caused by their defective products – known as Manufacturing Defects.

Definition of Product Liability

Product liability is the legal responsibility of a manufacturer, retailer, or supplier for a defect in their product that results in property damage, injury, or death to the end user. It holds those companies responsible for delivering safe and usable products to the marketplace while ensuring they are designed, tested, produced, and labeled properly and accurately. Without product liability laws consumers would suffer by not having a way to take action against companies if harm were caused by a defective product. Fortunately, there are numerous statutes protecting consumers in order to ensure safety when it comes to purchasing items from manufacturers and other suppliers.

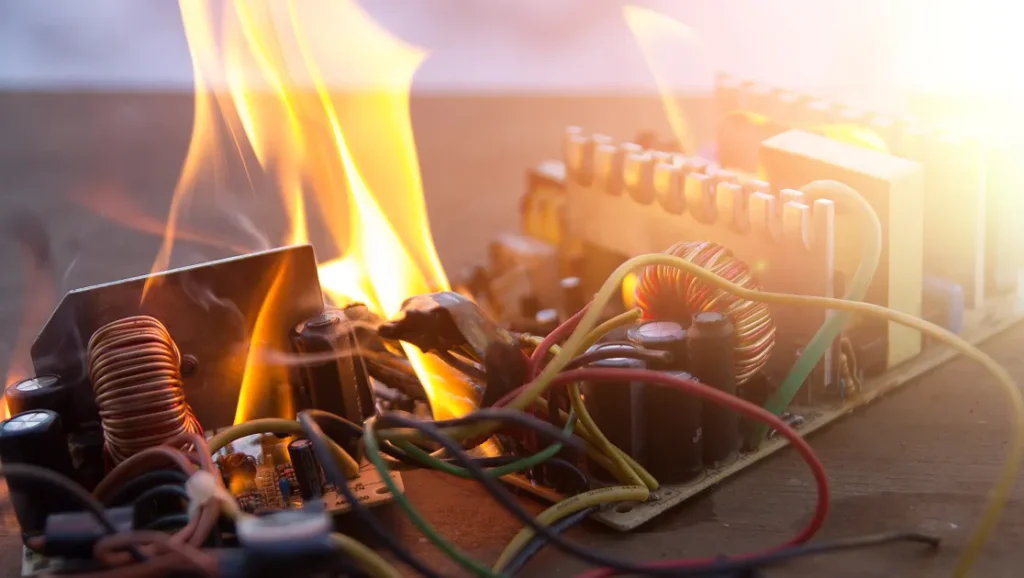

Overview of Manufacturing Defects

Manufacturing defects are a common occurrence within mass-produced items and, while they can appear to be minor inconveniences, they can often have serious implications. Issues such as a poor fitment of components, fraying or improper assembly, caustic chemical contaminants, and even wrong parts being included in a logical sequence can easily lead to malfunctioning hardware and expensive repairs.

Companies must remain vigilant throughout the entire process in order to guarantee that their products meet quality and performance standards before releasing them into the marketplace. If adjustments or modifications need to be made, it is important that they happen quickly and efficiently in order to prevent costly recalls and dissatisfied customers.

Types of Manufacturing Defects

Common types of manufacturing defects include:

- a lack of quality control resulting in incorrect placements

- incorrect measurements or improper counts

- errors in assembly, where parts fail to fit correctly together

- structural defects where items are assembled incorrectly, making them structurally unstable

- material defects where the wrong type of materials were used leading to wear and tear

It is extremely important for manufacturers to understand their responsibilities and adhere to them because if they do not, they could face severe financial penalties.

Causes of Manufacturing Defects

Manufacturing defects can be caused by a number of factors, including,

- inadequate design

- improper construction or assembly of components

- defective materials

- insufficient instructions on how to use the product

Poor quality control throughout any part of the production process can also significantly increase the risk for product liability due to an increased chance of parts being improperly created or assembled.

There is no excuse for these types of manufacturing defects – manufacturers must take all necessary steps to prevent them from happening in the first place in order to protect both their company and their consumers from any legal repercussions.

Examples of Manufacturing Defects

Examples of these defects include:

- a surface defect in which an area of the product has an obvious scratch or nick

- a dimensional defect in which the product’s dimensions do not meet specifications

- a material defect in which an undesired substance is present on the manufactured item

- poor assembly quality such as gaps between component parts

- inadequate sealing

Impact of Manufacturing Defects

The impact of manufacturing defects on product liability is undeniable. Consumers are often at a loss if an item does not live up to expectations, or worse, causes injury due to a defect. Companies should be held accountable for any such hidden flaws that render their product unsafe or ineffective. Strict laws must be enforced in order to ensure the safety of consumers across all industries. Not only does a faulty item cause financial losses, but it also damages consumer trust and may lead to a company’s reputation being negatively impacted. Product liability issues should never be taken lightly, and it’s essential that manufacturers invest time and resources into ensuring that their products are of high quality and safe for public use.

Legal Implications of Manufacturing Defects

Manufacturing defects can have serious legal implications. In many jurisdictions, businesses that produce and distribute products are responsible for any harm they cause due to a manufacturing defect.

If a product poses a risk of injury when used as intended, the distributor may be held accountable for any injuries or damage caused by the defect in a court of law.

To protect against liability, businesses should adhere to any laws and regulations governing their particular industry and make sure they produce safe products worthy of public trust. Strict compliance with these laws is essential for avoiding potentially costly penalties or civil action that could arise from harm caused by defective products.

If you have experienced manufacturing issues in products that you have purchased that have resulted in injury or loss of finances, contact our knowledgeable team of product liability lawyers today.